As France’s leading livestock-producing region, Brittany has a port to match the development of its agri-food economy.

Thanks to its Agribulk terminal, the Port of Brest can receive soy and rapeseed, soy cake, palm kernel cake, palm oil and other commodities quickly and flexibly.

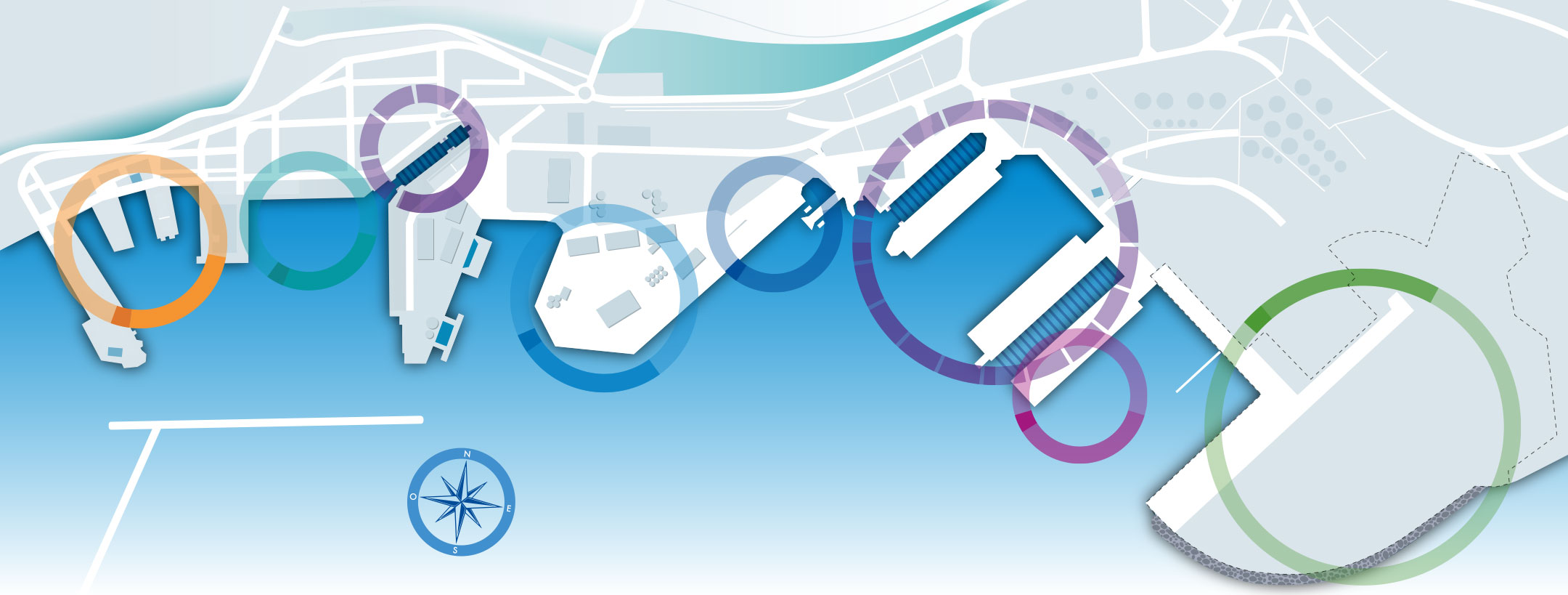

3 unloading docks (420 metres of dock space, with a 13m-deep draught);

7 flat storage warehouses, 3 of which are linked directly to the quays by conveyor belts (130,000 tonnes);

8 vertical silos linked to the docks by conveyor belts (32,000 tonnes);

1 rail/road, loading/unloading station;

130,000 tonnes of storage capacity.

These facilities can unload two ships simultaneously, store more than 130,000 tonnes of goods and transport 9,000 tonnes a day by road or rail.

Directly connected to the rail and motorway networks, this platform is linked to the whole world by sea (via feedering and cabotage).

This multimodal terminal is located on a 600-metre-long quay.

50,000 m² of open space storage;

1 RoRo (roll on, roll off) gangway;

4 mobile cranes for container handling;

Nearly 400 electrical outlets for refrigerated containers;

A rail spur (B gauge: which accepts special, high and wide wagons and goes as far as Paris).

Open 24/7, the terminal allows shipowners and shippers to optimise organisation and ensure rapid handling of goods and decreased layover time.

HACCP, ISPS Code, ISO 9001, ISO 14001 certified, opened 24/7

> Product of animal origin frozen, refrigerated or without temperature condition not intended for human consumption

Product of animal origin frozen, refrigerated or without temperature condition not intended for human consumption

Veterinary services, for vegetables controls from non-community countries, intended for animal consumption (grains, press cakes, seeds, vegetable oils).

Certification for animal goods checks from organic agriculture from non-EU countries

Ports of Brest and Paluden are certified EU-entry point for phytosanitary checks exclusively on wood.

Tugs, riggers, pilots, harbour masters, customs, seabord conscription’s office, hydrographics, phytosanitary and veterinary checks, stevedores, storage providers, forwarding agents, sips agents, shipchandler, logistics…

Land reserves for traffic development

Ship repair is a key activity in the Port of Brest, for example its dry dock No. 3 is one of the largest in Europe (and the 2nd largest in France).

Damen, a world-class player in ship repair and conversion, mainly operates dry docks 2 and 3. The dry docks are used for the maintenance, servicing and repair of ships of all tonnages. More specific vessels, LNG tankers and cruise ships can all undergo maintenance in Brest.

For Damen, 2022 was an exceptionally busy year:

Dry docks 2 and 3 were in use for 500 days total.

Dry dock 1 is available to manufacturers wishing to dry dock smaller vessels.

It is also used for downstream repairs and ship breaking.

These facilities will soon be joined by a careening area for small-scale ship repairs.

It will be equipped with a 650-tonne boat lift for handling ships in a dedicated dock,15m wide by 60m long.

The careening area will be equipped with multiple service terminals (various voltage capacities, water) and a careening water treatment system to comply with environmental standards.

Careening will be possible in a dedicated area for vessels, accessible by lift.

Dry Dock 1: 225x27m (entrance) / 34m (working area) entrance threshold at -4.4m draft, 1 30-tonne crane

Dry Dock 2: 338x55m, access probe -6.70m draft, 3 cranes from 12 to 90 tonnes

Dry Dock 3: 420x80m, access probe -7.30m draft, 3 cranes from 15 to 150 tonnes

QR1: 320m long, -8.50m deep water berth

QR4: 400m long, -9.30m deep water berth

High-performance equipment, technical expertise and adherence to deadlines are the hallmarks of this port.

The commercial port and ship repair facilities are ISO 9001 and 14001 certified.

In 2010, the Port of Brest inaugurated a new sand wharf, reserved exclusively for sand carriers transporting sand and other mineral bulk materials.

Increased processing capacity, with the new sand jetty able to handle twice the volume of sand and mineral bulk materials than before, meeting the growing demand for these materials in the region.

Strategic positioning: located at the tip of Brittany, BrestPort offers advantageous access to the construction and civil engineering markets, where sand and bulk materials are essential.

Efficient logistics, thanks to the proximity of processing and shipping facilities that facilitate the transhipment of materials, thereby reducing costs and lead times for customers.

Support for regional development: by improving processing capacity and facilitating the import of sand and bulk minerals, BrestPort is contributing to the region’s economic development by supporting the construction, infrastructure and public works sectors.

These facilities make BrestPort a key infrastructure for maritime trade, capable of keeping pace with demand for materials.

BrestPort is one of Brittany’s most important maritime entry points for the supply of energy products, particularly liquid hydrocarbons (oil) and liquefied gas. Hydrocarbon imports are close to one million tonnes each year, thanks to the following infrastructures:

an oil wharf equipped with three oil depots;

up to 130,000 m³ of storage facilities.

These wharves enable the oil terminal to accommodate two ships simultaneously, ensuring swift and efficient management of oil and gas imports.

The infrastructure provides greater capacity for large vessels, optimising the volume of oil and gas that can be handled simultaneously.

Modern storage and transfer facilities ensure a constant and secure flow of oil and gas, minimising unloading and storage times;

The wharves are equipped with optimised loading/unloading arms and fire-fighting devices, guaranteeing safe handling for oil and gas;

BrestPort is ideally placed to serve regional energy markets, situated as it is, ‘at the tip of Europe’. This therefore reduces transport costs and times;

With 130,000 m³ of storage facilities, the port provides an important strategic reserve for the region.

With around 25 calls and over 30,000 passengers a year, the Port of Brest is a leading port on the Atlantic seaboard.

In 2013, the Brittany Region launched a structural development plan for the Port of Brest, aimed at welcoming and developing marine energy-related industries by building new maritime infrastructures and developing available polder surfaces.

The Region has committed 220 million euros to the construction of this polder.

This crucial project has become a considerable asset: a 400m-long quay dedicated to heavy goods and 40 hectares of surface area, fully available in 2027 to accommodate wind energy industries.

A 400m-long quay with a 100m-deep handling platform capable of accommodating all types of handling (lifting by heavy load crane, hauling by SPMT)

Carrying capacity of 10 to 64t/m²

An 8m draught in the access channel and 12m quayside

40 hectares of industrial lots connected to the various networks

Heavy roadways linking the industrial lots to the new quay (40m wide) and the ship repair area (24m wide)

A car park with 1,100 spaces.

This has allowed Haizea, a company specialised in wind-turbine masts and monopiles, to assemble 62 masts for the Ailes Marines park in the bay of Saint-Brieuc.

The company will also be providing masts for the upcoming windfarms in Yeu-Noirmoutier and Dieppe-le-Tréport between 2024 and 2026.

Navantia-Windar has assembled several parts for the jackets used in the windfarm off the coast of Saint Brieuc.

Between 2023 and 2024, Eolink will be assembling the France-Atlantique 5MW demonstrator, including turbine and blade mounting in Brest.